Cold Ramming Carbon Electrode Paste For Ferro Alloys

Brand YENENG

Product origin China

Delivery time As per requirement

Supply capacity 200,000MT per year

Ramming paste is a critical part of the cathode. Early pot failures and reduced pot life may seriously impact smelter cost. Consistent and high quality ramming paste products installed according to optimised procedures are required to provide a basis for improved operation and longer pot life.

Product Overview

Product name: Cold ramming paste

Other Name: Ramming paste /Ramming mass /Electrode paste/ Cathode carbon Paste

Regular Package: Jumbo bag / 25Kg Waterproof bag

Origin: China

Appearance: Black mass

Features of Cold ramming Paste :

High quality Germany Binder

Fine size , best feedback by Aluminium Cell .

Our advantages

Powerful R&D technical strength;

Owns proprietary intellectual property rights;

Possessing sophisticated manufacturing equipment and inspection equipment;

Possessing advanced technics and production process;

Supreme Quality system;

Cost-effective;

China’s leading supplier in carbon and metallurgical industry with top reputation and larger market share;

Providing reliable sales and service;

Cooperation with hundreds of professional agents to develop win-win partner relationship worldwide.

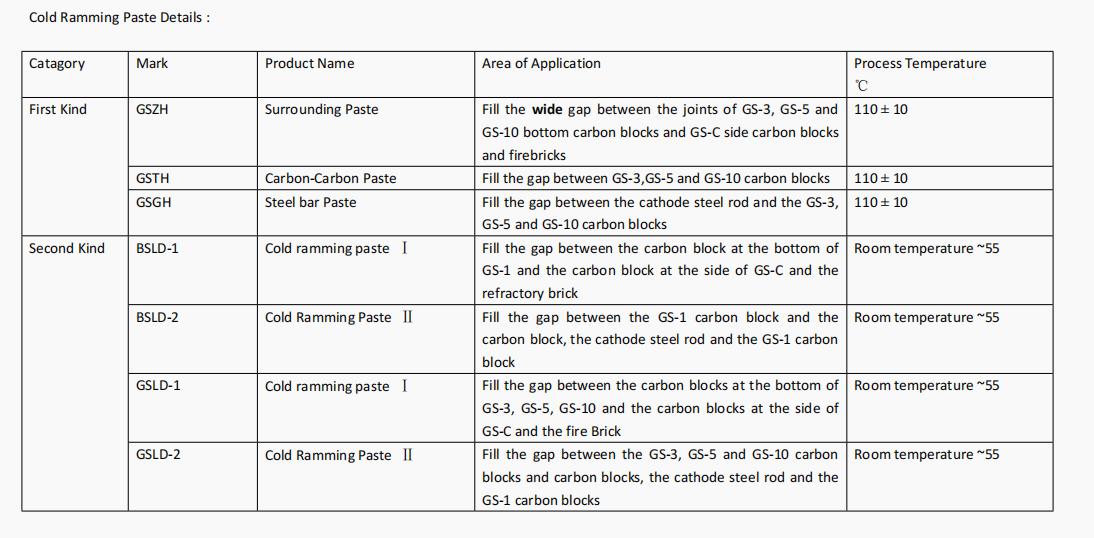

Products Parameters

Customized according to the Customer demand !

Application (1.Cold Ramming Paste has been successfully introduced for the following applications):

The main purpose of the ramming paste, both in the joints between the cathode blocks ,steel and Cathodes and in the peripheral seam, is to fill the voids between the prebaked blocks and prevent metal and bath from penetrating the cathode. Leakage of metal and electrolyte damages the cathode and may lead to premature pot failure.

1.Submerged Arc Furnaces For Ferro Alloys

CRP ramming is used in the walls and base of ferro alloys furnaces.

2.Ladles For Handling Molten Ferro Alloys

The cold ramming character of CRP simplifies the problems associated with achieving a good rammed density and thereby ensures good ladle life.

An additional advantage is that the fuming problem associated with hot ramming is minimized.

3.Pans Or Mould For Ferro Alloys

CRP is suitable for forming the shallow pans or moulds for casting pigs or ingots of ferro alloys.

4.Launders

CRP may be used for lining launders used for the pouring of molten metals or slag.

5.Iron Making Cupolas Using The Basic Process

CRP ramming can used to line the well walls and siphon box.

6.Aluminium Reduction Cell

Cold Ramming Paste (CRP) is being used successfully by many aluminum companies as an alternative to the conventional hot ramming materials.